Table of contents

- Why Planning Your Warehouse Layout Matters

- Key Considerations When Planning Your Layout

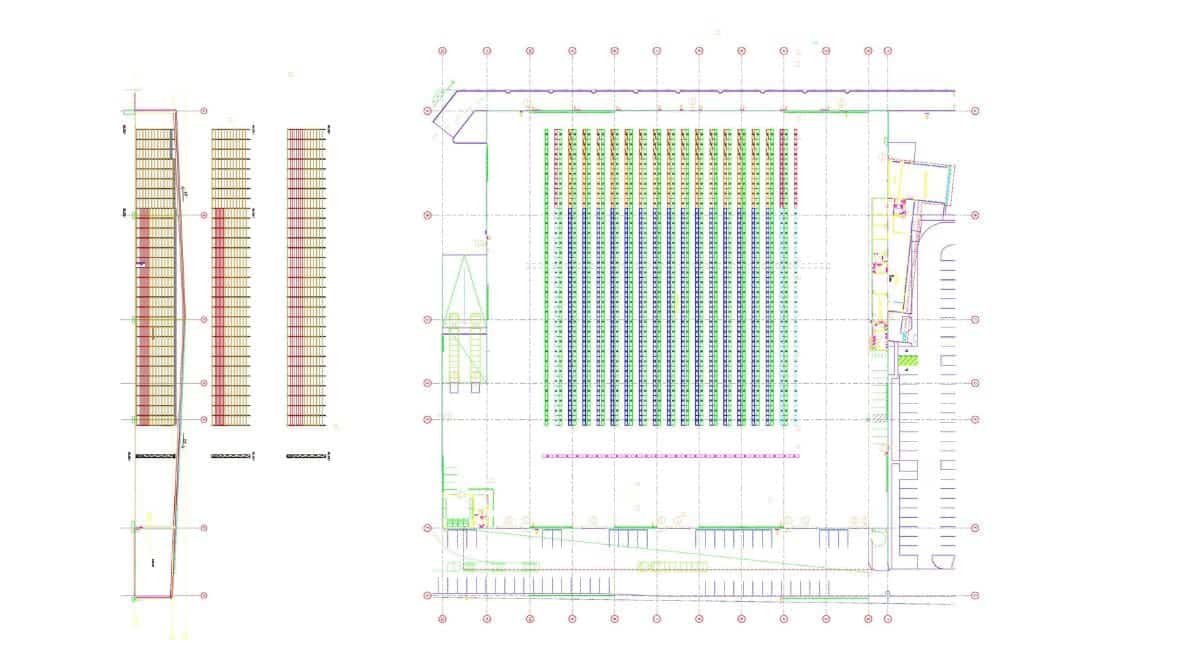

- Case Studies : Warehouse layout

- Final Thoughts: The Impact of a Well-Planned Layout

- Next Steps

- Frequently asked questions about warehouse layout

- What exactly is a warehouse layout?

- Why is warehouse layout so important, and how can it enhance productivity??

- How do I decide on the right warehouse layout for my business?

- Should I prioritise certain areas when planning the layout?

- How can racking systems improve warehouse layout?

- How do I account for future growth in my warehouse layout?

- What common mistakes do businesses make when planning their warehouse layout?

- How often should a warehouse layout be reviewed or updated?

- What is the impact of a well-planned warehouse layout on overall productivity?

When it comes to material handling in a warehouse, one of the most overlooked yet critical factors is layout. I always tell clients that an efficient warehouse layout isn’t just about where you store your products; it’s about how quickly and easily your workers can get to those products and move them through the space.

The less time your workers spend navigating aisles and moving between stations, the more productive they can be. Strategic planning of your warehouse layout can significantly reduce wasted time, energy, and, ultimately, money.

Racking systems hold a lot of weight, and incorrect installation can result in serious risks—collapsing racks, damaged goods, and dangers for workers. Getting it right from the start supports long-term efficiency and safety in your warehouse.

Why Planning Your Warehouse Layout Matters

In an efficient warehouse, every second counts. Picture this: if a worker spends just an extra minute per task navigating through cluttered or inefficiently organised aisles, that wasted time adds up quickly over the course of a day or week. Multiply that by the number of employees you have, and suddenly, you’re losing valuable hours of productivity every week—hours that could be spent fulfilling orders or processing inventory more efficiently.

- Choose the Right System: Take time to choose the right racking system based on your storage needs. Pallet racking is a great option for storing large quantities of materials but takes into account weight capacity, product dimensions, and overall workflow.

- Check Regulations: Research local building codes, safety standards, and permit requirements before finalising your design.

Key Considerations When Planning Your Layout

Key Considerations When Planning Your Layout

- Map Clear Paths: Ensure direct and unobstructed paths from point A to point B. This reduces unnecessary walking and helps workers move more quickly.

- Organise High-Traffic Areas: Place frequently accessed items closer to the main workstations to reduce travel time.

- Use Vertical Space: Don’t just think horizontally. Consider vertical storage solutions to free up floor space and reduce congestion.

- Plan for Growth: Ensure your layout can adapt to changes, whether it’s new inventory or increased demand. Future-proofing your layout is a wise investment.

Case Studies: Warehouse layout

Reducing movement in a distribution warehouse by 25%

Before:

We had one client with a distribution warehouse handling thousands of small orders daily. Their layout had high-traffic items stored all over the place, with workers having to walk long distances between picking stations. They didn’t have a clear plan for grouping items or managing frequently accessed products.

Workers were spending up to 40% of their time walking, and order fulfilment times were higher than they should have been.

After:

Total Racking Systems reorganised the warehouse by creating dedicated picking zones. Frequently picked items were grouped in close proximity to reduce travel distance. We also introduced gravity conveyors to move goods from the picking area directly to packing stations, eliminating manual transport.

Outcome: Order fulfilment times were reduced by 25%, and the number of walking workers had to do decreased by over 30%.

This streamlined the process and allowed the warehouse to handle more orders without adding additional staff.

Optimising Space in a Manufacturing Warehouse reduces time spent moving materials between production stages by 20%

Before:

Another client, a manufacturing company, had several heavy pieces of machinery scattered across the warehouse floor. This disorganised layout forced workers to take long, inefficient routes to move materials between production stages. Forklifts were having trouble navigating between machines, leading to delays and even safety concerns.

Frequent bottlenecks, and unnecessary downtime as workers waited for machines or forklifts to move products between areas.

After:

Total Racking Systems redesigned the layout to create clearer pathways for forklifts and workers. Heavy machinery was moved to one side of the warehouse, and dedicated lanes were introduced to allow easy movement of materials between stages. Additionally, we implemented a vertical storage system for tools and components to free up floor space.

Outcome: Worker movement was reduced by 15%, and the time spent moving materials between production stages dropped by 20%.

This not only improved productivity but also increased overall safety in the warehouse.

Improving Workflow in a Retail Distribution Centre increased packing productivity by 30%

Before:

A retail distribution centre suffered from poor flow in their packing area. Workers were constantly crossing paths, leading to confusion and inefficiency. The packing stations were also too close together, causing congestion as workers navigated through the space.

The packing process was slower than expected, and workers were frustrated with the cramped layout.

After:

Total Racking Systems redesigned the layout to include dedicated packing lanes with more space between workstations. Clear directional signage and mapped pathways were introduced to create a one-way flow system, preventing workers from crossing paths. We also moved packing materials closer to the packing stations to minimise the distance workers had to travel.

Outcome: Packing efficiency increased by 30%, and workers reported feeling less stressed and more productive with the improved workflow.

Final Thoughts: The Impact of a Well-Planned Layout

At the end of the day, planning your warehouse layout carefully is one of the most important things you can do to ensure efficiency and productivity. Whether you’re handling high-volume retail orders or managing complex manufacturing processes, a strategic layout helps minimise wasted time and reduces movement for workers. It also optimises the use of your space, making it easier to scale your operations as your business grows.

If you think your warehouse layout could use an upgrade, don’t hesitate to reach out. At Total Racking Systems, we specialise in creating customised solutions to make your warehouse more efficient, safe, and productive. Let’s work together to optimise your space for better performance.

Next Steps

- Learn More: Read our article on Maximising warehouse space with overhead solutions or Balancing storage density and selectivity in your warehouse or Benefits of warehouse racking for pallet storage

- Get a Quote: for Sydney pallet racking or learn how to Order pallet racking.

- Reach Out: For more information or assistance, contact Total Racking Systems.

Frequently asked questions about warehouse layout

What exactly is a warehouse layout?

A warehouse layout is the strategic organisation of space within a storage or distribution facility. It encompasses the placement of aisles, storage systems, picking zones, and workstations to promote safety, speed, and efficiency in daily operations.

Why is warehouse layout so important, and how can it enhance productivity??

A well-structured layout helps workers access products faster, reduces travel time, and streamlines day-to-day tasks. An organised space eliminates workflow bottlenecks, increases safety, and boosts order fulfilment speed.

How do I decide on the right warehouse layout for my business?

Consider your product types, order frequency, available floor space, and equipment needs when designing a layout. It helps to analyse current workflows, identify bottlenecks, and ensure safety regulations are met before finalising any design changes.

Should I prioritise certain areas when planning the layout?

Focus on high-traffic zones first. Ensure important items are placed closer to loading docks or packing stations to cut down on worker travel. Clear paths and efficient aisle widths also help prevent congestion and accidents.

How can racking systems improve warehouse layout?

Racking systems make it easier to store large quantities of goods while saving floor space. By using vertical storage, you free up space for movement and reduce clutter. Just remember to select a system that matches your product dimensions and weight requirements.

How do I account for future growth in my warehouse layout?

Design the layout with flexible storage solutions—like adjustable racking and modular shelving—so you can easily expand or reorganize as your business evolves. Planning ahead keeps you from having to redo your layout entirely when you scale up.

What common mistakes do businesses make when planning their warehouse layout?

Common pitfalls include ignoring vertical storage, creating narrow aisles that cause bottlenecks, and scattering frequently used items. Overlooking safety guidelines or placing equipment in cramped areas can lead to accidents and unproductive workflows.

How often should a warehouse layout be reviewed or updated?

Regularly review your layout—often annually or after major operational changes. Introducing new product lines, adopting new technology, or experiencing rapid growth are all reasons to reevaluate and adjust the existing setup.

What is the impact of a well-planned warehouse layout on overall productivity?

Proper planning allows workers to move goods faster, reduces downtime, and minimises the distance travelled during picking and packing. This can result in shorter order turnaround times, happier employees, and better customer satisfaction.