Colby & Dematic: Engineering Safety, Quality, and Compliance in Storage Solutions

Colby and Dematic uphold the highest standards of safety, quality, and compliance in their storage solutions through a comprehensive, multi-faceted approach [Previous response]. Their commitment begins with strict adherence to Australian Standards, specifically AS 4084 Steel Storage Racking, which governs both the design and operation of pallet racking systems [Previous response, 471, 479]. All Colby products, including ColbyRACK, are designed, engineered, and manufactured by Dematic Pty Limited, ensuring local expertise and control over the entire process

FIFO Warehouse Management: How the Right Pallet Racking System Can Transform Your Operations

Are you overwhelmed by stock coming in and going out of your warehouse? Implementing FIFO (first in, first out) management in your warehouse with the right pallet racking system in place you’ll reduce waste and increase efficiency.

What to Look for in Pallet Racking Installation Service

efficient space utilisation is necessary for businesses looking to optimise their operations. Enter racking installation services—a specialised solution that transforms ordinary warehouses and storage facilities into organised, productive environments. These services encompass a wide range of racking systems, from traditional pallet racks to advanced modular shelving, tailored to meet the unique needs of various industries. With the right racking installation, businesses can enhance their inventory management, improve accessibility, and maximise vertical space, ultimately leading to increased efficiency and cost savings.

How to choose a pallet storage rack system

Choosing a pallet storage rack system that suits your warehouse layout, product mix, and operational demands can have a lasting impact on efficiency and profitability. The size, weight, and turnover rate of your goods will guide you toward options like selective racking for frequent access, or drive-in racking for space-saving high-density storage. Equally important are safety standards and the capacity for future growth—an adaptable system ensures your operations stay on track as demands shift. By balancing cost with long-term reliability, you can set up a pallet storage rack solution that optimizes inventory flow, boosts productivity, and accommodates the evolving needs of your Australian business.

Minimise Product Damage with Smart Racking Configurations

Avoiding product damage in your warehouse starts with smart racking configurations. A poorly designed setup can lead to damaged inventory, inefficiencies, and wasted space. By tailoring shelving to your products, using protective accessories like upright protectors, safety clips and mesh decks, and ensuring proper installation, you can keep your stock safe while maximising efficiency. Investing in high-quality racking materials and adhering to Australian Standards (AS4084–2023) ensures long-term stability and safety.

Carton Live Storage (CLS) for Streamlined Order Picking & Efficiency

Carton live storage systems play a vital role in optimising warehouse operations by utilising gravity to streamline order-picking processes. These systems enhance storage capacity, improve accessibility, and reduce labour costs, making them a smart investment for warehouses and distribution centres. With various components such as shelving units, rack systems, and roller tracks, businesses can tailor their storage solutions to meet specific needs.

From pallet racking systems designed for high-volume storage to gravity-fed order picking solutions that boost efficiency, implementing the right system requires careful planning. This article explores the benefits, components, and types of carton live storage, along with key considerations for installation and maintenance.

Guide to Understanding Pallet Rack weight Capacity and How to Calculate

Explore the essentials of pallet rack weight capacity in this guide. Learn how to calculate load limits for beams and frames, understand the importance of even load distribution, and discover key safety practices to keep your warehouse operations running smoothly and safely.

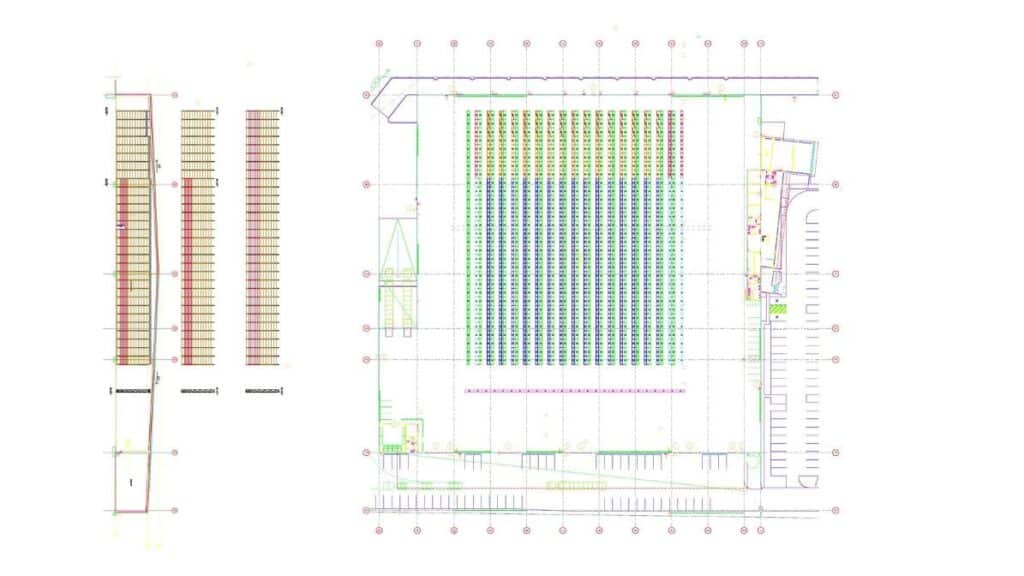

Plan Your Warehouse Layout in 2025 for Maximum Efficiency

Explore how strategic warehouse layouts reduce travel time, cut costs, and streamline workflows. Discover real-world examples of racking systems, machinery placement, and optimised paths that increase output and support a safer working environment.

Racking Installation: Your Guide to a Safe and Efficient Setup

Proper racking installation is essential. It’s not just about placing racks; it’s about prioritizing safety, making the most of your warehouse space, and creating a storage setup that will stand the test of time.

In this guide, you’ll find everything you need to know about planning, installation, and the qualifications involved. There’s also a quick FAQ section to clarify some of the most common questions about pallet rack installation.

Balancing Storage Density and Selectivity in your Warehouse

Efficient warehouse management requires balancing storage density with easy access to goods. Maximising storage density reduces costs and utilises space effectively, while maintaining selectivity ensures smooth operations.

This article explores ways to calculate and enhance storage density, highlights high-density racking systems like drive-in and push-back racking, and offers tips for selecting the best solution for your needs. With the right strategies, you can optimise space, streamline access, and boost efficiency in your warehouse.