Colby & Dematic: Engineering Safety, Quality, and Compliance in Storage Solutions

Colby and Dematic uphold the highest standards of safety, quality, and compliance in their storage solutions through a comprehensive, multi-faceted approach [Previous response]. Their commitment begins with strict adherence to Australian Standards, specifically AS 4084 Steel Storage Racking, which governs both the design and operation of pallet racking systems [Previous response, 471, 479]. All Colby products, including ColbyRACK, are designed, engineered, and manufactured by Dematic Pty Limited, ensuring local expertise and control over the entire process

How ‘PA Qu’ Makes Warehouse Shelves Just Right for All the Boxes

PA Qu revolutionises warehouse organisation by designing pallet racking systems based on actual usage rather than maximum capacity. Learn how this “just right” approach saves money, enhances safety, and promotes sustainability in warehouse storage solutions.

Common Pallet Racking Hazards and How to Mitigate Them

How to Mitigate the common pallet racking hazards that may occur in your warehouse. Risk Assessments are the first step to safety and developing work method statements. Read on to find out the common rack hazards and how to avoid them.

Minimise Product Damage with Smart Racking Configurations

Avoiding product damage in your warehouse starts with smart racking configurations. A poorly designed setup can lead to damaged inventory, inefficiencies, and wasted space. By tailoring shelving to your products, using protective accessories like upright protectors, safety clips and mesh decks, and ensuring proper installation, you can keep your stock safe while maximising efficiency. Investing in high-quality racking materials and adhering to Australian Standards (AS4084–2023) ensures long-term stability and safety.

Guide to Understanding Pallet Rack weight Capacity and How to Calculate

Explore the essentials of pallet rack weight capacity in this guide. Learn how to calculate load limits for beams and frames, understand the importance of even load distribution, and discover key safety practices to keep your warehouse operations running smoothly and safely.

Why Choose Colby Racking for Your Warehouse?

Looking to protect your warehouse racking from forklift damage? Colby Racking offers the ideal solution with Protect-a-Rack, UU-Beam, and compliance with Australian safety standards, ensuring durability, safety, and efficiency for any warehouse setup.

Height Specific Force Calculations:

Gone are the days of a one-size-fits-all mentality towards racking design. The AS 4084.1:2023 standards acknowledge the diverse needs of warehouses with varying ceiling heights and storage practices.

Pallet Racking Inspection Checklist as per AS4084:2023

In the pursuit of greener, more sustainable industrial solutions, Total Racking Solutions is leading the way with its commitment to eco-friendly practices.

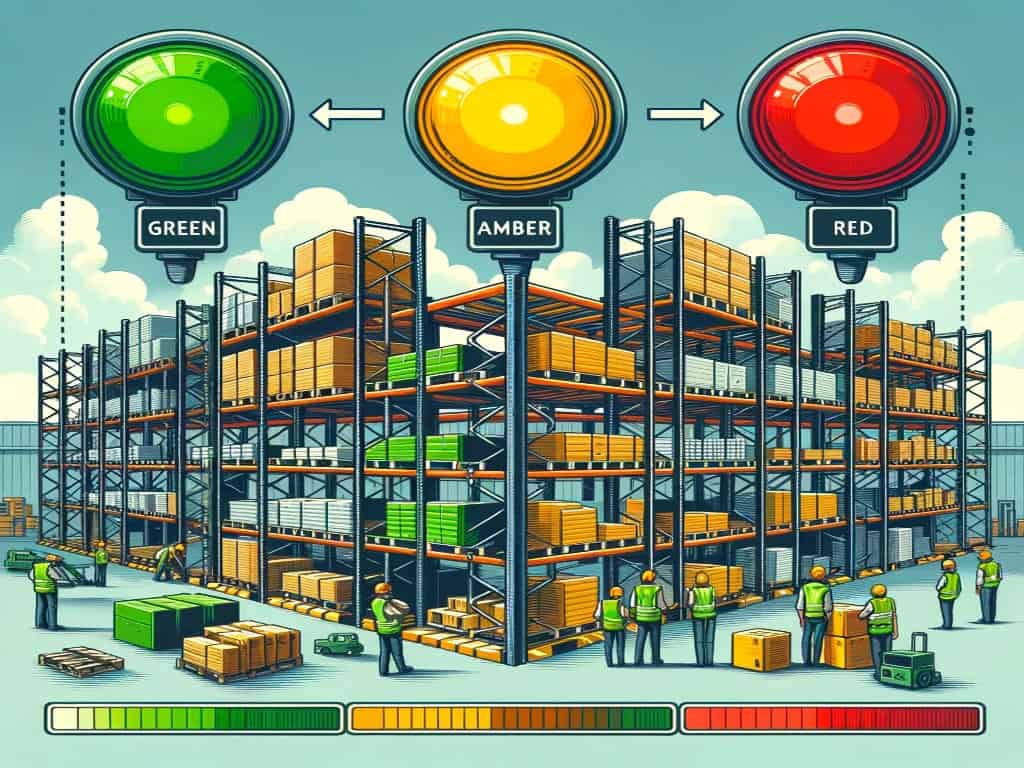

Pallet Racking damage, risk & Repairs: The Traffic Light System

Warehouse safety is important for protecting your goods and the safety of your workers. One critical aspect of warehouse safety involves properly assessing and classifying damage to racking systems. This post delves into the hierarchical colour-coding system designated by “green,” “amber,” and “red” levels of severity (risk) for racking damage classifications based on specific guidelines and standards.

Safe Working Load Sign: Knowing your load Capacity is essential for warehouse safety

Safe Working load signs are not just informational tools but are vital for compliance, safety communication, and the prevention of accidents. This comprehensive guide underscores the importance of SWL signs, delves into the risks of incorrect application, and outlines the standards and practices necessary to maintain a safe and efficient storage environment.